Spindle, Drag, Stream

Spindle, drag and stream finishing techniques have given rise to an innovative new generation of mass finishing machines. The differences to other technologies lie in the tremendous processing forces harnessed by the machine. This enables the material to be removed more selectively and faster than with any other surface finishing system. This technique can be extremely useful for intricate and “hard to reach” geometries where previous mass finishing processes were insufficient. Equipment can be used for a wide range of applications from deburring and mirror-finish polishing, to smoothing and polishing, as well as the edge rounding of cutting tools.

Unsure which is best for you?

We can help.

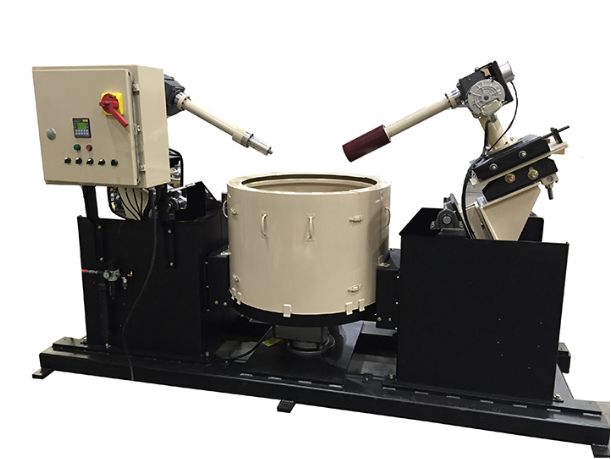

Roto-Finish VersaFlow Spin Finisher

Dimensions: 36″ tub speed or custom

- Parts that are processed in the Spin-Finish are normally parts that: cannot have part-on-part contact; are high value parts; or where a lean manufacturing single part flow is needed.

- Parts are fixed using collets or special tooling on the spindle.

- Rotating spindle tilts parts into rotating mass/slurry.

- The tub revolves at a range of speeds dictated by the need of aggression, the need of a more gentle action, or a light slurry. As the tub spins, it creates centrifugal energy and surface feet.

OTEC Stream Finisher

Dimensions: Can process work pieces of up to 400 mm in length and up to 20 kg in weight (including holder)

- First-class mirror finish even inside the flutes.

- Shorter processing times for edge rounding and polishing.

- Work pieces can be changed whilst the process is running.

- Number and design of work piece holders can be customized to suit requirements (1-5 holders depending on model of machine).

OTEC Drag Finisher

- Deburring, grinding or high-luster finish in quality otherwise only obtained through hand polishing; perfect surfaces can be obtained in just a few minutes.

- Work pieces are fixtured and “dragged” through media at particular angles that achieve nearly impossible finishes.

781-449-4160

781-449-4160