Centrifugal Disc

Centrifugal disc finishing is a widely used, aggressive, high energy, mass finishing technique. It incorporates a “bowl” design with fixed side walls and a rotating disc in the bottom of the bowl. Centrifugal force creates intense contact between the workpieces and the media, shortening time cycles and generating a finishing effect which can be up to 20 times more efficient than conventional vibratory finishing. The unique toroidal stream caused by the rotation of the “disc” enables aggressive work to be done in a short period of time. Disc finishing can be used for many different applications, from aggressive deburring to finishes requiring low Ra surfaces, and machines are available in wet or dry configurations from ½ to 10 Cu. Ft. It lends itself particularly well to smaller machined parts, forgings, stampings, and the jewelry industry, where hand polishing has been successfully reduced by 90% or more.

Unsure which is best for you?

We can help.

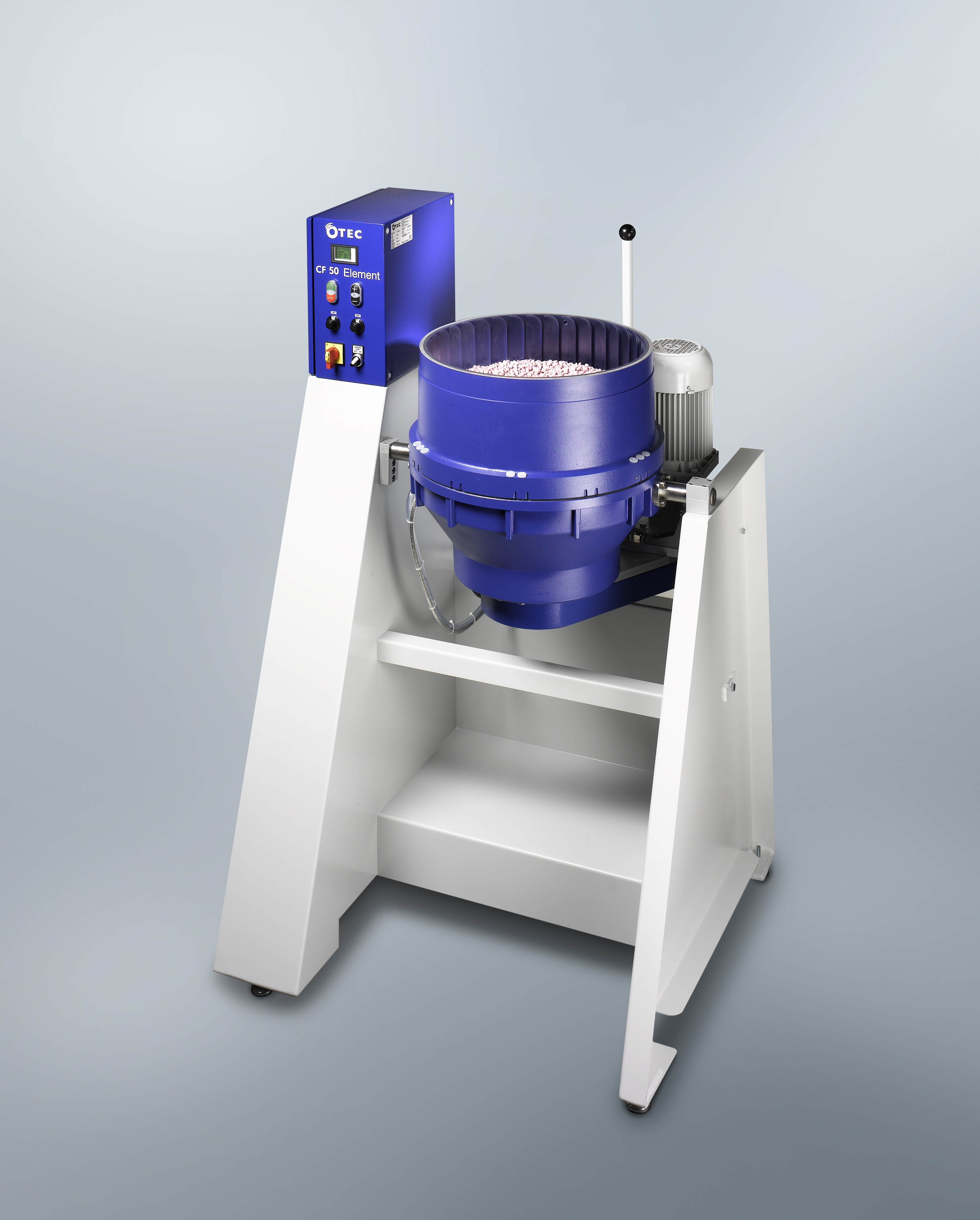

OTEC Element Centrifugal Disc Finisher

Dimensions: Modular in design and available as standard with 1 – 6 process drums.

- Deburring, smoothing, grinding and polishing – the entire range of applications with just one machine.

- Affordable because of its basic controls, while still including the robust and reliable process drum.

- Unique, patented gap system enables the gap to be adjusted to an accuracy of 0.05 mm. This variable setting of the gap between the disc and the drum wall enables a very fine grain polishing media.

- Available for both wet and dry finishing of workpieces.

OTEC CF-Series Centrifugal Disc Finisher

Dimensions: Modular in design and available as standard with 1 – 6 process drums.

- Deburring, smoothing, grinding and polishing – the entire range of applications with just one machine.

- Easy to operate. Speed, processing time, water/compound concentration, rinse cycles and all other main processes parameters can easily be set by means of the user-friendly Siemens touch screen control panel.

- Unique, patented gap system enables the gap to be adjusted to an accuracy of 0.05 mm. This variable setting of the gap between the disc and the drum wall enables a very fine grain polishing media.

- Available for both wet and dry finishing of workpieces.

Roto-Finish Roto-Max Centrifugal Disc Finisher

Dimensions: Working capacity is .75-7 cuft and 14 standard models are available depending on desired automation and separation options.

- A series of centrifugal disc machines from Hammond Rotofinish

- Roto-Max series comes in a variety of larger sizes providing a workspace of 1-7 cuft over other smaller centrifugal disc equipment.

- Up Flow® compound and water system cools the gap between the disc and the wear-ring or sidewall moving abrasive debris upward and out of the finishing chamber through a sidewall drain. This increases the life of the machine.

Roto-Finish Revolution Automatic Centrifugal Disc Finisher

Dimensions: 2, 3 and 6 cuft options available

- New patented “all-in-one” centrifugal disc machine from Hammond Roto-Finish, which features the RM-2 or RM-6 centrifugal disc .

- Machine has one main moving pivot point which, depending on which feature is activated, will move the process bowl to empty the media and part mixture onto the built-in separator.

- Built-in separator is also the return media hopper, so the media is automatically reloaded into the process chamber to start the operation over again.

- Compact and can be easily expanded to accept added features for material handling, or secondary processing steps.

781-449-4160

781-449-4160