Industrial Blast Rooms & Abrasive Recovery Systems

An abrasive blast room facility reduces blasting costs and environmental contamination by bringing blasting indoors, making possible the use of recyclable abrasives.

Whether you need an abrasive recovery system for your existing room or a complete blast room or dry stripping facility big enough to handle cargo aircraft, Fortune Metal can help you plan, budget, and erect a state-of-the-art blast facility, then train your employees to operate and maintain it. How much space do you need? Will you need more compressed air? Which abrasive types lend themselves to a mechanical recovery system vs. pneumatic (vacuum)? What size dust collector will I need? This Industrial Facility Planning Guide shows the advantages and disadvantages of different components available for your blast room.

Unsure which is best for you?

We can help.

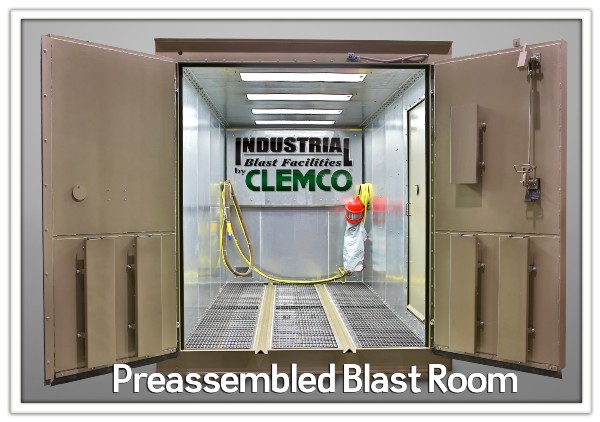

Pre-Assembled Blast Rooms

Dimensions: ‘ ‘7 x ’14 x ‘8 max dimensions

- Blast rooms arrive at your site ready to install. Connect the components and add power and air.

- Because the room must ship via truck, room dimensions are limited to 14 feet by 7 feet by 8 feet tall.

- Includes full area recovery – pneumatic or mechanical – as well as lights, control panel, one full-width, full-height door, and a separate personnel door.

Custom Engineered Blast Rooms

- Equipment and accessories for contained blasting. The product line includes blast room enclosures, abrasive recovery systems, and dust collection systems.

- Range of standard engineered recovery solutions (described below) designed to handle the differing flow characteristics of commonly employed blast media

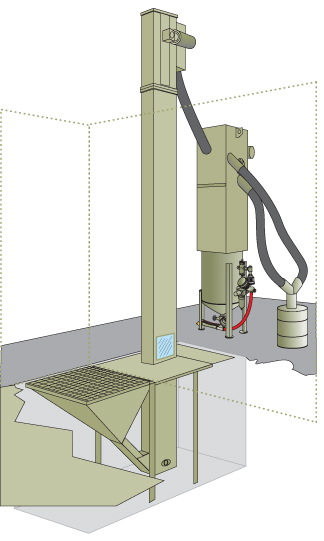

Abrasive Recovery Systems

To make the most of recyclable abrasive, an efficient abrasive recovery system automates the media recovery and cleaning processes. There are four major types of recovery systems to consider:

- Surface Mount & Shovel-In Abrasive Recovery Systems

- Belt Conveyor Abrasive Recovery System

- Flat-Trak Surface-Mount Abrasive Recovery System

- M-Section Pneumatic Abrasive Recovery System

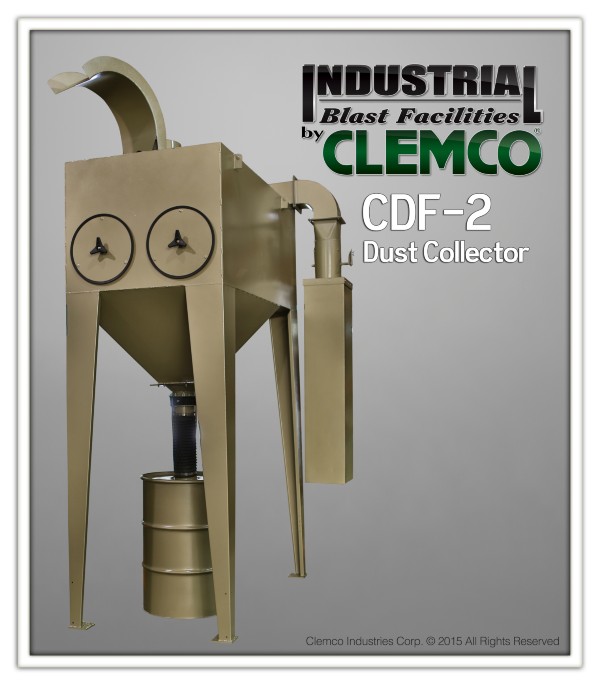

Blast Room Dust Collection Systems

Dimensions: “86 x “50-“410 x “172-“187 (various sizes)

- Efficient reverse-pulse style collector used to provide ventilation for all sizes of industrial blast facilities. Units are of simple, modular design and are easy to install, operate, and maintain.

- CDF dust collectors ventilate blast room enclosures, providing room air changes for visibility and engineered solutions for controlling respiratory protection exposure limits to dust.

781-449-4160

781-449-4160