Vibratory

Vibratory finishing, also known as a type of “mass finishing”, is a more complex operation than most realize. Much like any manufacturing operation, there are several variables that affect the end results. The compound type and concentration, water flow rate, amplitude and RPM of the finishing chamber, type, size, and shape of the media, and type of equipment utilized all play a role. Masking and plugging can also be utilized to protect certain surfaces. Our primary vibratory finishing equipment partner is Hammond Roto-Finish. We have chosen to work with them because the quality and robustness of the machines they build is unsurpassed in the industry. Their product portfolio is diverse, covering every process and part size, and their full-service urethane department provides high quality relines (hyperlink to reline) and refurbishment for their equipment as well as those made by other manufacturers.

Unsure which is best for you?

We can help.

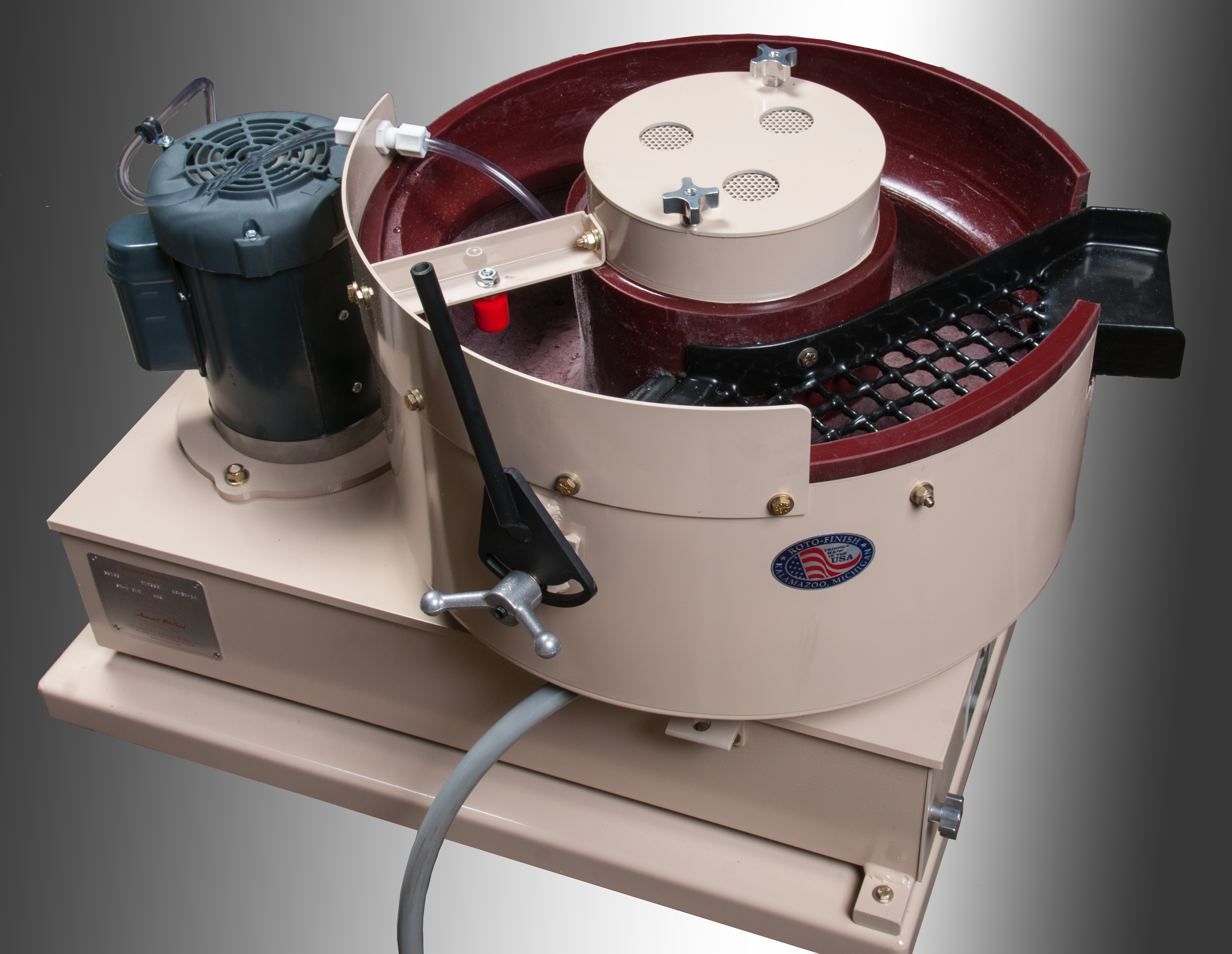

Roto-Finish ST-1 Heavy Duty Benchtop Vibratory Finisher

Dimensions: 34″ Length, 18.5″ Bowl Rim Height, 21.5″ Diameter Processing Bowl, 16″ Discharge Height

- Deburring, finishing, drying, burnishing, cleaning — all in one machine.

- Versatility and good value are the key benefits of the ST-1. Capable of turning heavy medias or gentle enough to finish soft metals.

Vibra-Finish FSV-25 & FSV-50 Small Floor Standing Vibratory Finisher

Dimensions: 1 and 2 Cuft Capacity

- High-energy, mass finishing vibratory system with a unique space-saving footprint and compact design.

- Low-profile, adjustable amplitude and lead angle. Straight wall construction and 3/8 inch thick polyurethane liner.

- Flow meter with adjustable nozzle provides flow-thru solution control. Easily changeable drain plug.

Roto-Finish Gemini Series Vibratory Finisher

Dimensions: 4, 7, 11 Cuft Capacity

- Robust action — heavy duty coil springs

- U-shaped process channel with textured sidewalls. Flat bottom versions also available.

- 4 polyurethane pop-in drain sizes included.

- Parts separation system with hand lever operated gate.

Roto-Finish HR-Series Vibratory Finisher

Dimensions: Available in several sizes, allowing for part size, geometry, and the process cycle time needed.

- A machine built to last — heavy duty welded steel; certified pressure vessel tank head.

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl; Full 90º Wrap-Around Separation Screen; Water-Driven Compound System.

Roto-Finish HR-Series Flat Bottom Batch Vibratory Finisher

Dimensions: Available in several sizes, allowing for part size, geometry, and the process cycle time needed.

- Ideal for large component finishing

- A machine built to last — heavy duty welded steel; certified pressure vessel tank head; Polyurethane liner is cast, not sprayed on.

- Used for batch processing, the machine is loaded and unloaded by piece by hand. For small parts and part on part, it is unloaded through the unload plug or door.

- Some applications are possible with a magnetic belt separator.

Roto-Finish HR-Series Combo Vibratory Finisher

Dimensions: Available in several sizes, allowing for part size, geometry, and the process cycle time needed.

- Designed for a very high range of performance

- Advantages over the standard HR Machine include higher amplitude, more uniform part processing, better feed for longer parts.

- Used for batch processing, the machine is loaded and unloaded by piece by hand. For small parts and part on part, it is unloaded through the unload plug or door.

- Capable of Continuous or Batch Processing

Roto-Finish HR-Series Long Radius Combo Vibratory Finisher

Dimensions: Available in several sizes, allowing for part size, geometry, and the process cycle time needed.

- Designed for a very high range of performance

- Advantages over the standard HR Machine include higher amplitude, more uniform part processing, better feed for longer parts.

- Used for batch processing, the machine is loaded and unloaded by piece by hand. For small parts and part on part, it is unloaded through the unload plug or door.

- Capable of Continuous or Batch Processing

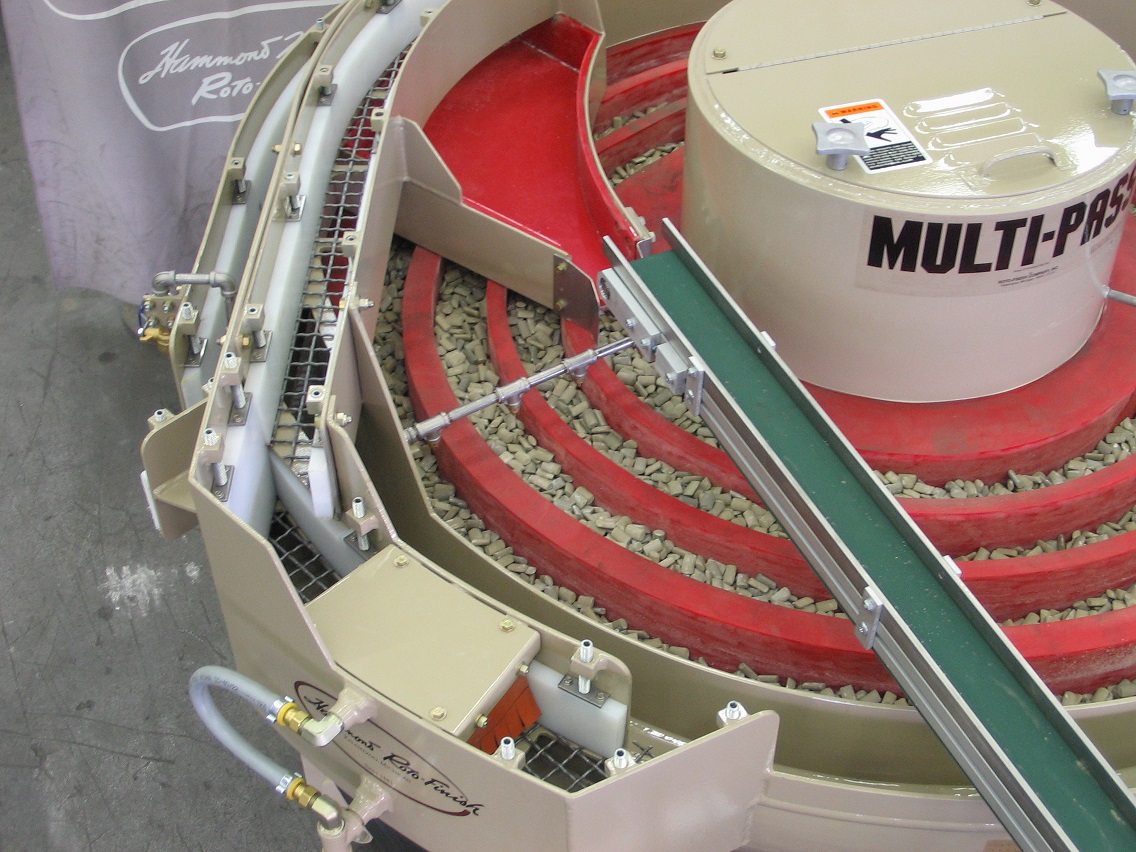

Roto-Finish Multipass Series

Dimensions: Available in several sizes, allowing for part size, geometry, and the process cycle time needed.

- Full, u-shaped process channels ensures full media roll (no siding) and more turns of the part as it advances.

- Can operate as a continuous process machine using part to media ratios used in conventional processes.

- Available as a MPC (Combo) which offers the potential for a drying channel on the process bowl. This reduces the need for external systems requiring more floor space.

C+M Topline 300DB & 600DB Vibratory Tub Finisher

Dimensions: 3 cuft; 25”x 38″ x 37″ (300DB), 6.5 cuft; 29″ x 46″ x 44″(600DB)

- A simple, inexpensive vibratory finishing machine that replaces hand deburring.

- Built for small part, high production deburring, degreasing, cleaning and polishing needs.

- Backed by a one-year warranty

781-449-4160

781-449-4160